Description

Why Anderson Selexx Full Line CNC Router?

- Increase productivity by reducing the loading & unloading operations.

- Optional automatic bar code or part labelling for improved part identification.

- Scissor lift indexing table in combination with the suction loading system allows for the automatic loading of sheets.

- Automatic pusher and dust suction device push parts onto a motorized conveyor while cleaning the spoil board, making it ready to load the next sheet.

- High-speed nesting cell with a single operator.

- Industrial Anderson CNC router with superior cutting speeds for maximum throughput.

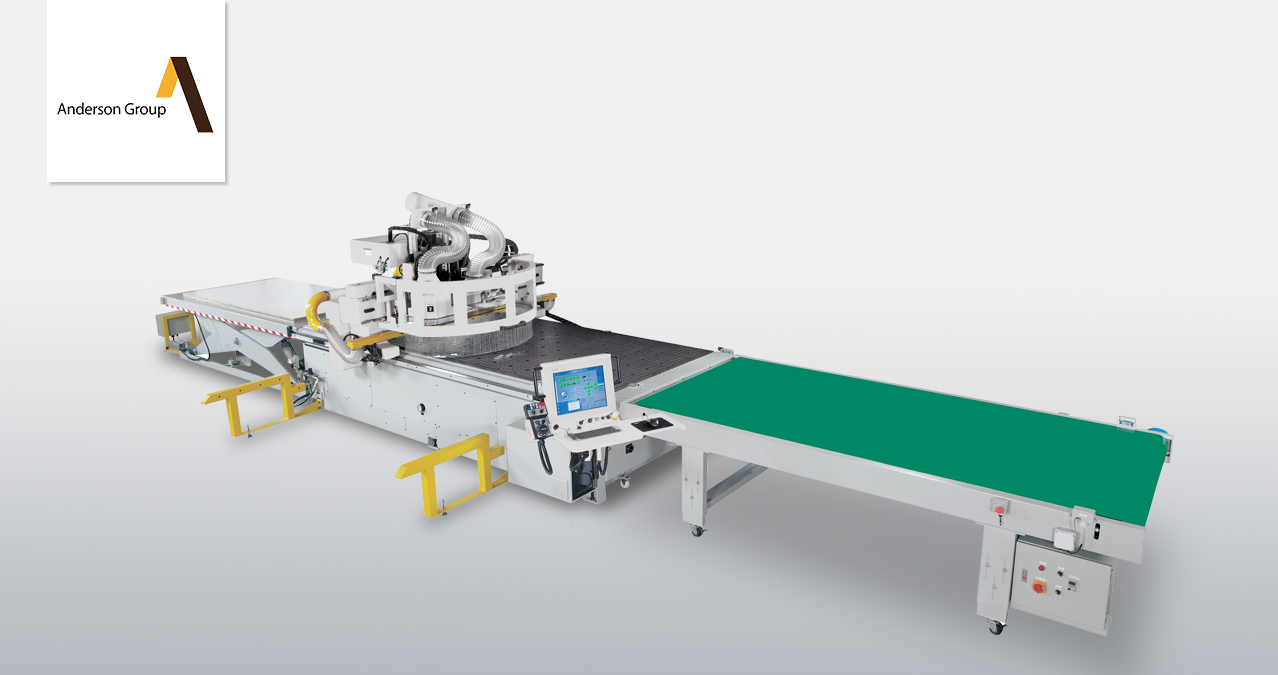

The AndersonFully Automatic CNC Router Line Consists of:

- Automatic scissor lift table with three-ton load-bearing capacity for full bundles of panel materials.

- Anderson Selexx CNC Router Models MATE (4×8’), PAL (5×10’), and CHIEF (5×12’) can be equipped with fully automated loading and offloading systems.

- Dust gate to remove any dust and debris from the bottom of the processed sheet.

- Automatic conveyor table for the offloading of finished parts.

- It can also be equipped with automatic part labelling.

- Automatic loading and offloading system.

Loading Device

- The Suction Cup Loading Device and Integrated Vacuum Cleaning System is standard on the Anderson Full Line CNC Router.

- The Integrated Vacuum Cleaning System ensures that all dust and debris is removed from the machine table prior to loading the next sheet.

- The six (6) industrial-strength vacuum cups will load and position sheet material onto the tabletop without scratching the surfaces and align them perfectly against the pop-up pins.

Automatic labelling system

- A popular option to add to the nesting line is the automatic label printer.

- Through its stand-alone software and controller, the label printer effectively reduces the amount of cycle time needed by completing the application of labels before the panel is cut.

Reviews

There are no reviews yet.