Powerful Heavy Duty Radial Arm Saw Series.

The Original Saw 16” Heavy Duty Radial Arm Saws are the best in the industry. Featuring 3 and 5 horsepower motors, they are capable of operating in industrial wood cutting environments. Original Saw Radial Arm Saws are capable of a wide variety of wood cutting operations including miter cutting, bevel cutting, compound miter cuts, as well as dado operations. They are a smooth cutting saw that has a rigid feel and are capable of making accurate and repeated cuts.

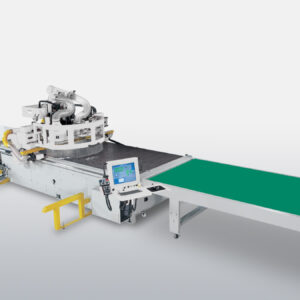

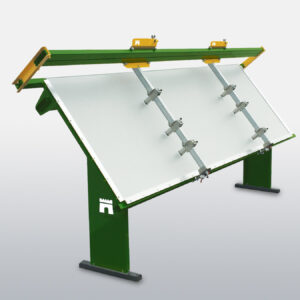

These radial arm saws weigh in at a massive 500 pounds. They are constructed of cast iron and aluminum for vibration free operation. These saws are much more than a radial arm saw. They are a stable cutting platform for many crosscutting and dado operations. Our saws can be outfitted with our OS Series TM extension tables and manual measuring systems for safe support and measuring of your material. Our American made saws are built in our Northern Iowa facility with American castings and motors.

There are several blade options for the Heavy-Duty Radial Arm Saw. These saws use a 16″ carbide tipped blade. We carry a 40 tooth and a 60-tooth blade for general purpose cutting. For fine cross cutting, we suggest an 80 tooth or 120 tooth blade. We also carry a 16″ 120 tooth carbide tipped blade for cutting plastic. Blades are sold separately from the saw.

Reviews

There are no reviews yet.