5 axes CNC Machining Centre profit H350R

- Small footprint – minimal space requirement!

- 5 axes router spindle, solid construction with 12 kW liquid cooled motor

- Drawing = programming, intuitive operating software

- Software including 3D cabinet software “F4-Design” for presentation, parts list and connection to the machine

- Gantry design, synchronised drive, solid construction for maximum performance

- The drilling head covers the whole working field

- High quality dual circuit vacuum clamping system with 100 mm vacuum pod height

- Large Y dimensions for maximum processing depth

- F4®Solutionsready

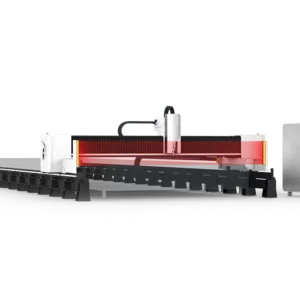

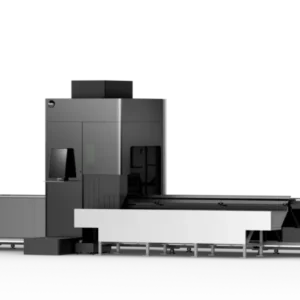

5 axes CNC Machining Centre profit H500R

- 5 axes router spindle, solid construction with 12 kW liquid cooled motor

- Drawing = programming, intuitive operating software

- “F4®Integrate” software including 3D cabinet software “F4-Design” for presentation, parts list and connection to the machine

- Possibility of 5 axes processing with “F4 Solid” powered by AlphaCam

- The drilling head covers the whole working field

- High quality dual circuit vacuum clamping system with 100 mm vacuum pod height

- 4 sided door and window processing with automatic delivery, s-motion consoles

- Workpiece thickness up to 250 mm

- F4®Solutionsready

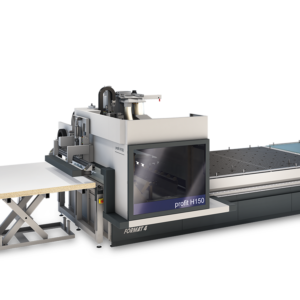

5-axis Nesting CNC machining centre profit H150

- Powerful electrospindle with 5 axes for unlimited processing possibilities

- Intelligent SMART ZONING vacuum management system with pendulum operation

- Five sizes for every workshop: 16.38, 19.38, 22.32, 22.43 and 22.61

- Front stop row set back for unrestricted machining of individual workpieces with a 3-4 or 5-axis spindle

- Large Z passage size of 200 mm offers flexible machining of high workpieces.

- Loading and unloading units as well as automatic labelling on the loading table

- Up to 36 tool positions

- F4®Solutionsready

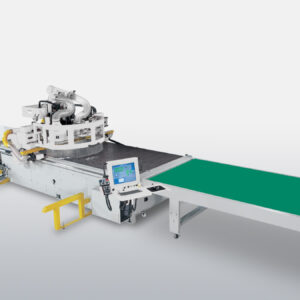

ANDERSON | SELEXX FULL LINE CNC ROUTER

High-speed nesting line for maximum throughput.

The Anderson Selexx Full Line CNC Router is a fully integrated automatic nesting CNC router line that greatly reduces cycle times by shortening the loading and unloading operations. The full line system allows for automated part labelling, automatic loading and offloading capabilities to the already full-featured Anderson Selexx Series CNC Router. Available as both a complete line or in customized selections, the Selexx Full Line CNC Router can be configured to meet your workflow demands in a fully functional package. These features are designed to increase production by minimizing the loading and unloading cycle time and improved part identification resulting in faster assembly times.