CANTEK | AF04 TRACK FEEDER

An all-purpose feeder intended to assist with feeding small workpieces,

The Cantek AF04 Track Feeder is specifically designed for feeding small workpieces which can not be fed properly using a conventional 3 and 4 roller feeders. The (3) synthetic rubber belts run on (5) feeder wheels which are closely coupled together. The result is the workpiece is held between the rollers allowing for the feeding of short and/or small material. The universal stand allows you to easily adjust the height and position of the feeder. It can also be positioned from a horizontal to vertical feed. The AF04 can be easily adapted to your shaper or table saw.

CANTEK | BS600-2H 2-HEAD WIRE BRUSH MACHINE

Produce distressed wire brush flooring and paneling with ease!

The Cantek BS600-2H 2-head wire brush machine is designed to remove the soft grain between the growth rings to produce distressed wood flooring, paneling, and more. Following the wire brush head is a nylon brush that is designed to remove any raised fibers that appear from the wire brushing. With variable frequency inverters to control the brush RPM and feed speed you have ultimate control over your finished aesthetic.

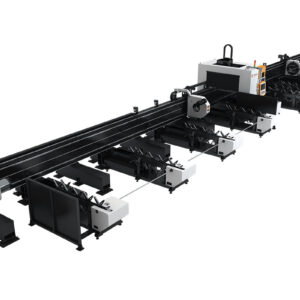

CANTEK | MX340 AUTOMATIC EDGEBANDER

High quality edge banding results for cabinet parts and case goods.

The Cantek MX340 Automatic Edgebander is a compact edgebander capable of applying up to 3mm thick edge tape on cabinet parts and more. It comes equipped with high frequency motors on both the end trim and top & bottom trim. In addition it is equipped with PVC radius scraping and buffing units. It’s compact design and affordable price point make it the ideal edge banding solution for the small cabinet shop who does not require pre-milling.

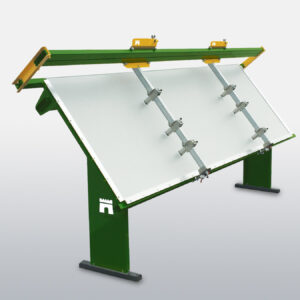

CASTLE USA | AT 4‘ X 12’ FACE FRAME ASSEMBLY TABLE

Professional woodworking assembly table.

The Castle USA AT-Race 4′ x 12′ Face Frame Assembly Table is an open back assembly table that features redesigned quick-clamps with center mounted switching for easy access from both sides. The clamp arm is steel ensuring a long lasting lifespan. The stainless steel bottom bracket features an air driver holster built right in. The open back feature gives you more work area and can handle oversize frames without taking up valuable shop space. This assembly table is an essential addition to your inventory of professional woodworking tools.

CNC Drill and Dowel Machining Centre D-Jet

- CNC machining in the smallest of spaces 3.5 m2

- Fully automatic insertion of anchors and glue.

- Various cabinet connections can be processed

- Up to 4 workpieces simultaneously

- Intuitively designed software F4Integrate

- F4®Solutions ready

CNC Machining Centre c-express 920 classic

- CNC productivity in just 3.4 m²

- Drawing = programming, intuitive operating software

- Woodflash software for cabinet planning 2D / 3D incl. connection to machine

- Cabinet construction-complete processing

- Three sided formatting using a router spindle

- F4®Solutionsready

CNC Machining Centre creator 950

- Complete processing for interior design in only 5 m²

- Simple programming – quick simulation – efficient production

- All inclusive: 4 sided formatting as standard

- Traditional processing from above – simple loading

- Get started straight away: maximum productivity without set-up times

- F4®Solutionsready

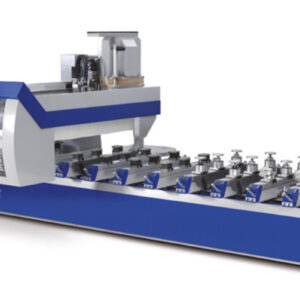

CNC Machining Centre profit H08 classic

- Small footprint – minimal space requirement!

- Drawing = programming, intuitive operating software

- “Woodflash” software

- Gantry design, synchronised drive, solid construction for maximum performance

- Automatic measuring system of the tool length

- Perfect nesting with the matrix table made from phenolic resin

- F4®Solutionsready

CNC Machining Centre profit H200R

- Small footprint – minimal space requirement!

- Drawing = programming, intuitive operating software

- Software including 3D cabinet software “F4-Design” for presentation, parts list and connection to the machine

- Gantry design, solid construction for maximum performance

- The drilling head covers the whole working field

- High quality dual circuit vacuum clamping system with 100 mm vacuum pod height

- F4®Solutionsready

CNC Machining Centre profit H300R

- Small footprint – minimal space requirement!

- Drawing = programming, intuitive operating software

- Software including 3D cabinet software “F4-Design” for presentation, parts list and connection to the machine

- Gantry design, synchronised drive, solid construction for maximum performance

- The drilling head covers the whole working field

- High quality dual circuit vacuum clamping system with 100 mm vacuum pod height

- Large Y dimensions for maximum processing depth

- F4®Solutionsready