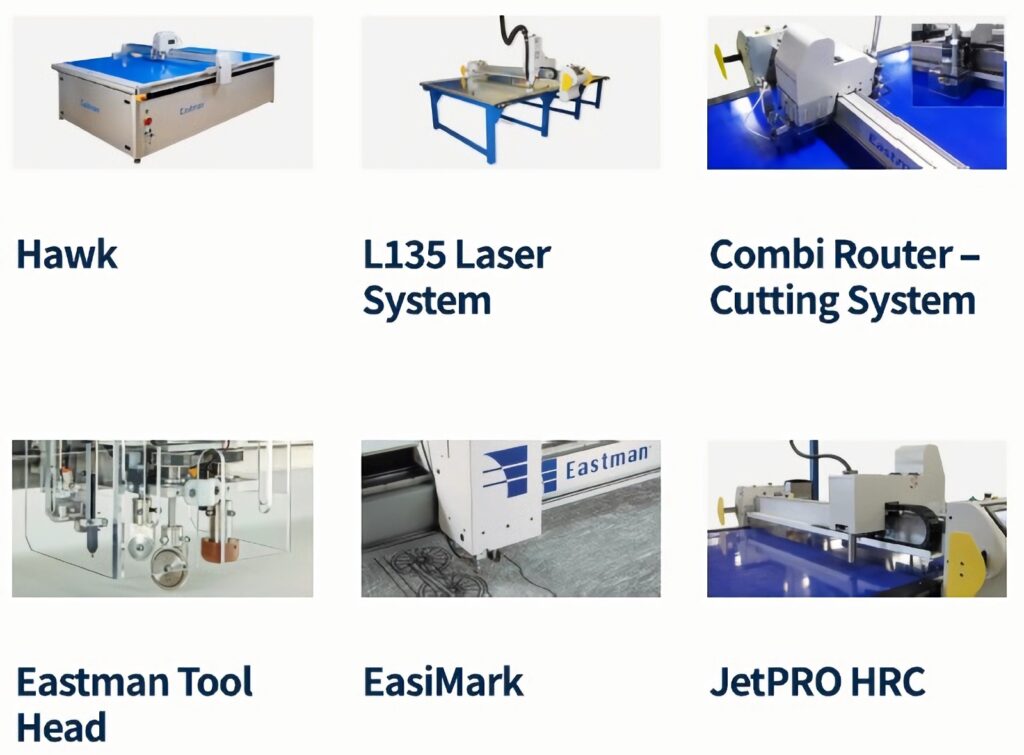

The EM Series offers advanced, computerized cutting systems designed for exceptional accuracy and consistency. Built to handle single, low, and high-ply cutting tasks, these systems deliver reliable performance across a wide range of applications. Featuring high-precision cutting tools, they provide unmatched versatility—even for the most challenging materials. Available in multiple sizes to accommodate everything from prototypes and small batches to full-scale production, the EM Series adapts easily to your workflow. A selection of optional accessories further enhances system capabilities, streamlining related tasks and boosting overall operational efficiency.

An automatic cloth fabric oscillating knife cutting machine is a specialized type of knife cutting machine that uses an oscillating (back-and-forth) blade to cut fabric. These machines are designed to offer high precision and efficiency, making them ideal for cutting a variety of materials in the textile and garment industry. CNC oscillating knife cutting machine is carried on the multi-tool cutting head-Vibration knife, Oblique knife, Circular knife, Punching knife, Milling knife, Punch roller and Marking pen. CCD camera and Projector are optional for more precise cutting.

Model | iGK-1625(Size can be customized) |

Working Size | 1600(W)*3000mm(L) |

Dimensions | 3500*2200*1200mm(L*W*H) |

Machine body | Welded high strength integrated bed |

Platform | Aerospace aluminum vacuum adsorption platform |

Platform adsorption material | 4mm felt |

Tool | Vibrating knife |

Cutting speed | 200-2600mm/s |

Translatory velocity | 500-2800mm/s |

Cutting thickness | 0.1-40mm(The actual materials shall prevail) |

Cutting accuracy | 0.05mm(The actual materials shall prevail) |

Operating system | Zhongrui |

Vacuum pump | 9KW vacuum pump |

Drive part | Taiwan straight square rail and rack |

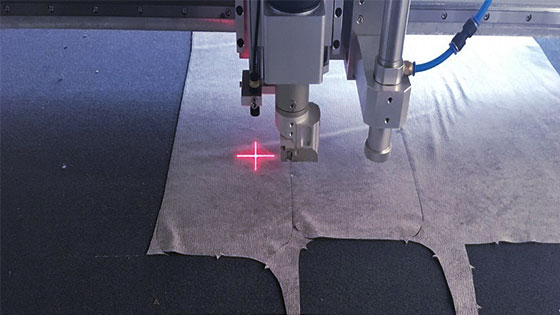

Miscellaneous function | Cross red light location |

Motor drive | Full servo motor drive |

Electric device | Chint/Omron |

Voltage | AC220V/380V,50Hz |

Optional tool | Round knife, punching knife, pneumatic knife, multi-layer knife, supporting knife, half cutter, oblique cutter, milling cutter, etc. |

Automatic trade mark registration.

Fully automatic feeding.

Full servo control.

Full process system control,

Material collection device.

Auto feeding, Auto crop and Auto correction.

Auto four side sewing.

Server control intelligent production.

Automatic material receiving.

SPV data collection.

Automatic fixed length cutting.

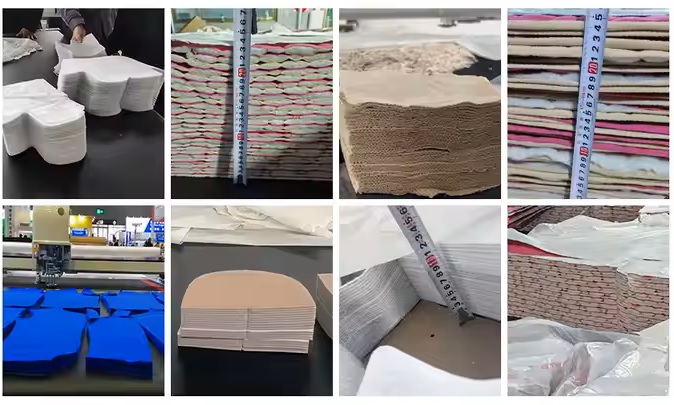

Cutting style:

Straight Knife Continous Up-down Cutting

Cutting Material:

Nonwovens, Linen, canvas, Chenille, woven fabric, sofa cover, UV fabric, PVC curtain, fur, faux fur, brushed, plush, tufting, wool, lmitation sweater collar, and so on.

Production Capacity:

650 pairs of pants per hour,

500 pieces of clothing per hour,

6000 pieces of medical clothing per hour,

500 sets of furniture sofas per hour,

600 sets of car interiors per hour,

8000 sets of plush toys per hour

Control System:

Compatible with any version of CAD

software Other functions Mobile cutting

device, automatic feeding device, pattern

scanning, adsorption bed

Main components:

1. Automatic multi-layer cutting bed.

2. automatic cloth spreading machine.

3. air floatation table.

Working Range:

1700*2500MM/2000*3000MM

2300*3000MM/2600*3000MM

Cutting length:

No limitation with automatic fabric feeding system.

Cutting Thickness:

0.1mm–110mm (compressed fabric, after vacuum adsorption)

Cutting Speed:

0-70m/min

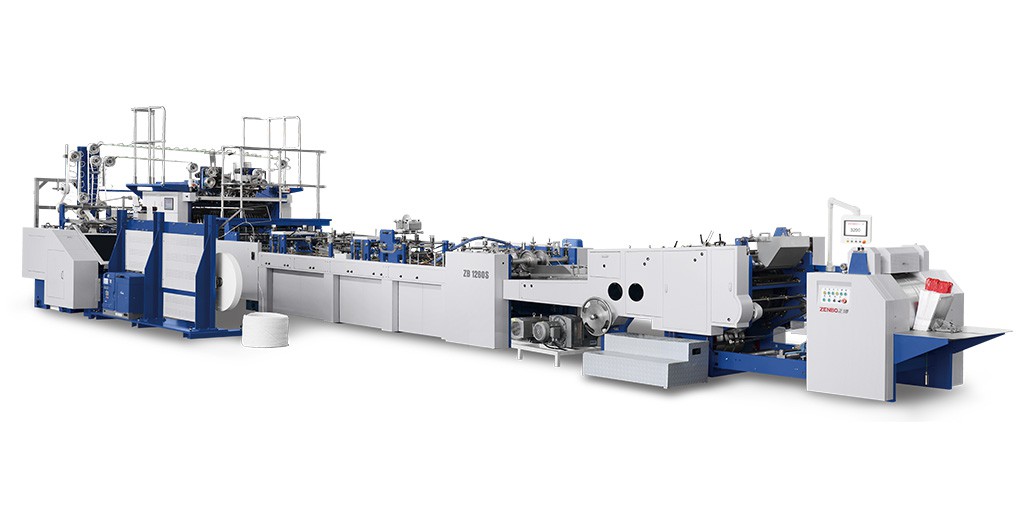

| No. | ZB1200CT-450S |

| Max.One Sheet(L*W) | 1200*600mm |

| Min.One Sheet(L*W) | 340*220mm |

| Paper Weight | 120-250gsm |

| Bag Width | 110-450mm |

| Bottom Width | 50-180mm |

| Bag Tube length | 190-570mm |

| Top Folding Depth | 30-60mm |

| Top Reinforced Paper Weight | 200-500gsm |

| Top Reinforced Paper Width | 90-430mm |

| Top Reinforced Paper Length | 25-50mm |

| Bottom Cardboard Weight | 250-400gsm |

| Bottom Cardboard Width | 44-174mm |

| Bottom Cardboard Length | 104-444mm |

| Production Speed | 40-80bags/min |

| Total/Production power | 52.5/31.5KW |

| Voltage | 380V |

| Total weight | 21.8T |

| Machine size(L x W x H) | 21500*6000*1800mm |

| Glue Type | Water Base Glue and Hot-melt Glue |

* Reduce the fiber damage in the process, to ensure the fiber length.

* Different types of specifications to meet different customer needs.

* The new internal structure, from the source to prevent the generation of dust; fully enclosed body, isolated personal and equipment direct contact to protect personal safety.

* High degree of automation, convenient and simple operation.

* Additional safety such as fire prevention and fire extinguishing devices.

* Special feeding device protects fiber length and ensures safe opoeration.

* Additional humidification and heat preservation systems ensure the quality of fiber processing.Advantages of technology upgrade

* Reduce the fiber damage in the process, to ensure the fiber length.

Automation & Continuous Cutting:

The automatic feeding system cooperates with the circulating cutting control system to realize automatic feeding (no need for manual drawing) and then automatic cutting. It is the first version after cutting, no need to stop, it can automatically feed and then automatically cut the next version, continuously cut into roll material without manual intervention!

One machine can be configured with different types of cutting tools to complete the cutting requirements of multiple materials at one time, without the need to replace cutting tools, convenient and fast automatic switching.

High-precision and high-performance accessories for the whole machine, the machine is more stable and not easy to damage, the maintenance is few, the life can be stable for more than 10 years.

| Cutting speed | Maxi 1500mm/s | ||

| Cutting Thickness | 0.2-110mm | ||

| Fixing | Vacuum absorption | ||

| Cutting Precision | ±0.2mm | ||

| Transmission interface | Ethernet port | ||

| Format compatible | AI software, Auto cad, Coral draw and all box software | ||

| Transmission materials | High precision rack and pinion | ||

| Drive motor | Japan’s Mitsubishi servo motor and drive | ||

| Mode | 1625 | 1825 | 2025 |

| Cutting area | 2500x1600mm | 2500x1800mm | 2500x2000mm |

| Overall dimension | 327x230x140cm | 327x250x140cm | 377x284x140cm |

| Standard configuration | Configuration A (Single cross beam,4 axis, Oscillating knife + pen) Configuration B (Single cross beam,4 axis, Oscillating knife + notch) | ||

| Configuration C (Single cross beam,6 axis, Oscillating knife+ Round knife + pen + notch) | |||

| Configuration C (Double cross beam,4 axis, Round knife + pen) | |||

| Configuration E (Double cross beam,6 axis, Oscillating knife + Round knife +pen + notch) | |||